Products

Stainless Steel Wire Rope mei SS316 en SS304

Produkt parameters

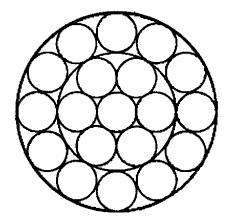

| Konstruksje |

| ||||

| Nominale Diameter | Approximate Gewicht | Minimum Breaking Load oerienkommende To Rope Grade Of | |||

| 1570 | 1670 | 1770 | 1870 | ||

| MM | KG/100M | KN | KN | KN | KN |

| 0.5 | 0.125 | - | 0.255 | - | - |

| 1 | 0.5 | - | 1 | - | - |

| 1.5 | 1.125 | 1.9 | 2.02 | 2.15 | 2.27 |

| 2 | 2 | 3.63 | 3.87 | 4.11 | 4.35 |

| 2.5 | 3.125 | 4.88 | 5.19 | 5.5 | 5.81 |

| 3 | 4.5 | 7.63 | 8.11 | 8.6 | 9.08 |

| 4 | 8 | 12.8 | 13.7 | 14.5 | 15.3 |

| 5 | 12.5 | 19.5 | 20.7 | 22 | 23.2 |

| 6 | 18 | 30.5 | 32.4 | 34.4 | 36.3 |

| 7 | 24.5 | 43.9 | 46,7 | 49,5 | 52.3 |

| 8 | 32 | 51.5 | 54.8 | 58.1 | 61.4 |

| 9 | 40,5 | 68.6 | 73 | 77.4 | 81.7 |

| 10 | 50 | 93.4 | 99,4 | 105 | 111 |

| 11 | 60,5 | 112 | 119 | 126 | 1333 |

| 12 | 72 | 122 | 129 | 137 | 145 |

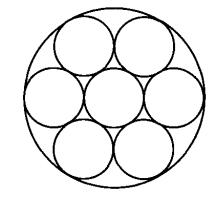

| Konstruksje |  | ||||

| Nominale Diameter | Approximate Gewicht | Minimum Breaking Load oerienkommende To Rope Grade Of | |||

| 1570 | 1670 | 1770 | 1870 | ||

| MM | KG/100M | KN | KN | KN | KN |

| 1 | 0.51 | 0.83 | 0.88 | 0.93 | 0.99 |

| 1.5 | 1.14 | 1.87 | 1.99 | 2.11 | 2.22 |

| 2 | 2.03 | 3.32 | 3.54 | 3.75 | 3.96 |

| 2.5 | 3.17 | 5.2 | 5.53 | 5.86 | 6.19 |

| 3 | 4.56 | 7.48 | 7.96 | 8.44 | 8.91 |

| 4 | 8.12 | 13.3 | 14.1 | 15 | 15.8 |

| 5 | 12.68 | 20.8 | 22.1 | 23.4 | 24.7 |

| 6 | 18.26 | 29.9 | 31.8 | 33.7 | 35.6 |

| 7 | 24.85 | 40.7 | 43.3 | 45,9 | 48,5 |

| 8 | 32.45 | 53.2 | 56.6 | 60 | 63.4 |

| 9 | 41.07 | 67.4 | 71.6 | 75,9 | 80.2 |

| 10 | 50.71 | 83.2 | 88,5 | 93.8 | 99.1 |

| 11 | 61.36 | 100 | 107 | 113 | 119 |

| 12 | 73.02 | 119 | 127 | 135 | 142 |

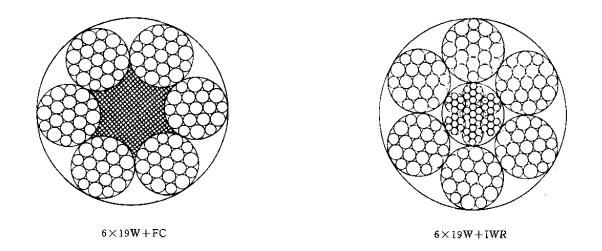

| Konstruksje | ||||||||||

| Nominale Diameter | Approximate Gewicht | Minimum Breaking Load oerienkommende To Rope Grade Of | ||||||||

| Fiber Core | Steel Core | 1570 | 1670 | 1770 | 1870 | |||||

| FC | IWS | FC | IWS | FC | IWS | FC | IWS | FC | IWS | |

| MM | KG/100M | KN |

|

|

|

|

|

|

|

|

| 1.5 | 0.83 | 0.81 | 1.12 | 1.31 | 1.19 | 1.39 | 1.26 | 1.47 | 1.33 | 1.56 |

| 2 | 1.48 | 1.44 | 1.99 | 2.33 | 2.12 | 2.47 | 2.25 | 2.62 | 2.38 | 2.77 |

| 2.5 | 2.31 | 2.25 | 3.12 | 3.64 | 3.32 | 3.87 | 3.51 | 4.1 | 3.71 | 4.33 |

| 3 | 3.32 | 3.24 | 4.49 | 5.24 | 4.78 | 5.57 | 5.06 | 5.91 | 5.35 | 6.24 |

| 4 | 5.9 | 5.76 | 7.99 | 9.32 | 8.5 | 9.91 | 9.01 | 10.51 | 9.52 | 11.1 |

| 5 | 9.23 | 9 | 12.48 | 14.57 | 13.28 | 15.49 | 14.07 | 16.42 | 14.87 | 17.35 |

| 6 | 13.3 | 13 | 18.6 | 20.1 | 19.8 | 21.4 | 21 | 22.6 | 22.2 | 23.9 |

| 8 | 23.6 | 23 | 33.1 | 35.7 | 35.2 | 38 | 37.3 | 40.3 | 39.4 | 42.6 |

| 10 | 36.9 | 36 | 51.8 | 55.8 | 55.1 | 59.4 | 58.4 | 63 | 61.7 | 66,5 |

| 12 | 53.1 | 51.8 | 74.6 | 80,4 | 79,3 | 85,6 | 84.1 | 90,7 | 88.8 | 95,8 |

| 14 | 72.2 | 70,5 | 101 | 109 | 108 | 116 | 114 | 123 | 120 | 130 |

| 16 | 94.4 | 92.1 | 132 | 143 | 141 | 152 | 149 | 161 | 157 | 170 |

| 18 | 119 | 117 | 167 | 181 | 178 | 192 | 189 | 204 | 199 | 215 |

| 20 | 147 | 144 | 207 | 223 | 220 | 237 | 233 | 252 | 246 | 266 |

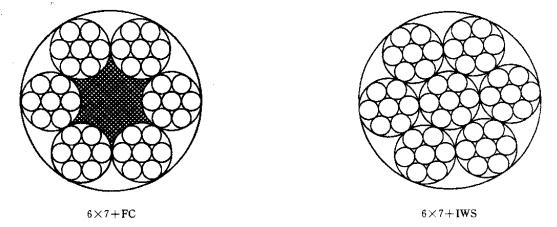

| Konstruksje | ||||||||||

| Nominale Diameter | Approximate Gewicht | Minimum Breaking Load oerienkommende To Rope Grade Of | ||||||||

| Fiber Core | Steel Core | 1570 | 1670 | 1770 | 1870 | |||||

| FC | IWS | FC | IWS | FC | IWS | FC | IWS | FC | IWS | |

| MM | KG/100M | KN | ||||||||

| 0.5 | 0.092 | 0.09 | 0.127 | 0.149 | 0.135 | 0.158 | 0.144 | 0.168 | 0.152 | 0.177 |

| 1 | 0.367 | 0.36 | 0.511 | 0.596 | 0.543 | 0.634 | 0.576 | 0.672 | 0.608 | 0.71 |

| 1.5 | 0.826 | 0.81 | 1.15 | 1.34 | 1.22 | 1.42 | 1.29 | 1.51 | 1.37 | 1.59 |

| 2 | 1.47 | 1.44 | 2.08 | 2.25 | 2.21 | 2.39 | 2.35 | 2.54 | 2.48 | 2.68 |

| 3 | 3.3 | 3.24 | 4.69 | 5.07 | 4.98 | 5.39 | 5.28 | 5.71 | 5.58 | 6.04 |

| 4 | 5.88 | 5.76 | 8.33 | 9.01 | 8.87 | 9.59 | 9.4 | 10.1 | 9.93 | 10.7 |

| 5 | 9.18 | 9 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.5 | 16.7 |

| 6 | 13.22 | 12.96 | 18.7 | 20.2 | 19.9 | 21.5 | 21.1 | 22.8 | 22.3 | 24.1 |

| 8 | 23.5 | 23.04 | 33.3 | 36 | 35.4 | 38.3 | 37.6 | 40,6 | 39.7 | 42.9 |

| 10 | 36.72 | 36 | 52.1 | 56.3 | 55.4 | 59,9 | 58.7 | 63,5 | 62 | 67.1 |

| 12 | 52.88 | 51.84 | 75 | 81.1 | 79,8 | 86,3 | 84.6 | 91,5 | 89.4 | 96,6 |

Seis punten foar omtinken by it brûken fan RVS tried tou

1.Don't brûke de nije RVS tried tou direkt op hege snelheid en swiere lading

De nije roestfrij stiel tou moat net brûkt wurde direkt op hege snelheid en swiere lading, mar rinne foar in perioade fan tiid ûnder lege snelheid en medium load betingsten. Neidat it nije tou is oanpast oan 'e steat fan gebrûk, dan stadichoan fergrutsje de rinnende snelheid fan' e tried tou en de opheffing lading.

2.De roestfrij stiel tou kin net loslitte fan 'e groove

As de roestfrij stiel wire tou wurdt brûkt mei de pulley, nim dan omtinken dat de touwen soarch kin net loskeppele út de pulley groove. As de tried tou bliuwt te brûken nei it fallen fan de pulley Groove, de tried tou wurdt geperst en misfoarme, kinked, brutsen, en brutsen stringen, dat sil serieus koarter de tsjinst libben fan de tried tou. As it tou brekt, sil it faaks slimme gefolgen hawwe.

3.Don't druk op de RVS tried tou

De roestfrij stiel wire tou moat net sterk yndrukt om foar te kommen ferfoarming tidens gebrûk, of it sil liede ta wire breakage, strand breakage, of sels tou breakage, dat sil koarter de libbensdoer fan 'e tried tou en bringt operasjonele feiligens yn gefaar.

4.Don't wrijven mei oare objekten as de roestfrij stiel tried tou rint op hege snelheid

Wannear't de RVS wire tou rint op hege snelheid, de wriuwing tusken de RVS tou en de objekten bûten de tsjil Groove is de wichtichste reden fan iere wire break.

5.Don't wind it RVS tried tou willekeurich

Wannear't it RVS tried tou wurdt wûn op 'e trommel, it moat wurde regele sa kreas mooglik. Of de stielen wire tou wurdt skansearre tidens operation.This sil feroarsaakje de tried breakage, dy't direkt beynfloedet de libbensdoer fan 'e stielen tried tou.

6.Don't overload it RVS tried tou

As de RVS tried tou wurdt oerladen, it sil fluch tanimme de mjitte fan squeeze deformation, en de mjitte fan slijtage tusken de binnenste stielen tried en de bûtenste stielen tried en de oerienkommende tsjil Groove sil bringe serieuze skea oan de feiligens fan operaasje en koarter de libbensdoer fan de pulley.

Oanfraach